Hard Wax Oil Warnings and Warranties

Limited Warranty

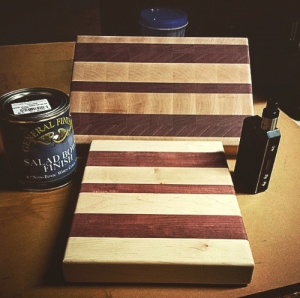

General Finishes products must be tested to your complete satisfaction before using. General Finishes will not be responsible for color satisfaction, misapplication, nor compatibility with other manufacturers' products. General Finishes will be responsible only for the cost of our products, and not for costs such as labor, damage or project replacement.

Contamination and Compatibility

Our finishes are engineered as a system and are compatible with each other. General Finishes cannot guarantee an ideal refinish when applying our products on top of or combined with another company's products or over surfaces that have been in contact with waxes, polishes or sprays containing contaminants such as silicone. Test for adherence and aesthetics before beginning.

FIRST AID: Seek immediate medical attention if symptoms occur due to the following. EYE CONTACT: Remove any contact lenses. Flush eyes with water for 20+ minutes while lifting upper and lower eyelids. SKIN CONTACT: Wash thoroughly after handling. INHALATION: Move to fresh air. Loosen tight clothing. If not breathing, if breathing is irregular, or if respiratory arrest occurs, trained personnel should provide artificial respiration or oxygen. INGESTION: Call physician immediately. Wash out mouth with water. Do not induce vomiting unless directed to do so by medical personnel. Never give anything by mouth to an unconscious person.

Prop 65 WARNING: No chemicals were found in this product which are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

DANGER: COMBUSTIBLE LIQUID AND VAPOR. HARMFUL OR FATAL IF SWALLOWED. CAUSES EYE IRRITATION.

DANGER: Can enter lungs and cause damage. DANGER: Keep out of reach of children. Keep away from heat and flame. Use only with adequate ventilation. Do not breathe vapor or mist. Do not swallow. Avoid contact with eyes. Keep container tightly closed when not in use. Wash thoroughly after handling.

Enduro Water-Based Conversion Varnish

Enduro Water-Based Conversion Varnish

Enduro Water Based Stain Blocker Primer

Enduro Water Based Stain Blocker Primer

Enduro Water-Based Tintable 2K White Poly

Enduro Water-Based Tintable 2K White Poly

Enduro Water-Based Pro Series White Polyurethane

Enduro Water-Based Pro Series White Polyurethane

Hard Wax Oil & Hardener

Hard Wax Oil & Hardener

Gel Stains

Gel Stains

Pro Image Flooring Topcoat

Pro Image Flooring Topcoat

Jen Poly Brushes

Jen Poly Brushes

Stir Stix

Stir Stix

Ultraflex Softback Sanding Sponge

Ultraflex Softback Sanding Sponge

TDS: Oil Based Wood Bowl Finish - 2020-03

TDS: Oil Based Wood Bowl Finish - 2020-03