We know of many customers that have achieved great results from buffing Arm-R-Seal with auto polishes, providing that the finish has cured for 7 to 10 days.

As with all products that are not manufactured by General Finishes, always test for compatibility on a hidden area of your project before getting started.

The problem areas on your table are probably caused by surface contamination from oils, waxes or cleaning products used over the years.

Contaminants from dusting sprays that contain silicone will also impact the appearance and adherence of a finish - silicone is almost impossible to remove. Oil soaps and wax can also cause adhesion failures. This may be why the finish is performing differently on the leaves vs the table top. Adhesion failure is often more obvious in the deepest patterns of grain because the contamination is driven deep into the grain.

John Mosconi of Sting King Lutherie in Akron, Ohio takes us on his journey of refinishing this mandola.

Step 1: Prep and Sealing

You can lightly buff with 0000 steel wool and General Finishes Orange Oil Furniture Polish - nothing too aggressive.

Arm-R-Seal Oil-Based Topcoats are made with the highest-quality urethane resin, making them extremely durable and long-lasting. Formulated to be wiped on with a cloth or applied with a foam brush, this ambering finish penetrates to provide deep-down protection for that "natural" look.

There are several techniques by Jeff Jewitt of Homestead Finishing Products:

Using Mirka Royal Micro sandpaper, always start with 1500-grit sandpaper. Begin with a small area, make 2-3 passes, then evaluate results. Go to a heavier grit if surface irregularities are not fully removed. Finish with 1500-grit paper.

General Finishes offers a complete line of oil based, water based and wax products. Application techniques differ between oil based products and water based products.

Although Arm-R-Seal rarely needs thinning because of its low viscosity, it can be thinned with up to 10% mineral spirits - more than that may thin the solids content too much.

Thinned Arm-R-Seal will be diluted but can be stored without risk of separation.

Arm-R-Seal can be sprayed successfully, but we prefer hand application methods because it is very easy to spray too much in one area. If you choose to spray, use very thin coats and watch for runs (large drips that run down the side of your project).

If you notice a run, immediately wipe or brush it out. If you correct a run promptly, you will not see a mark. However, dried runs can be difficult to remove.

We recommend an oil-based finish such as General Finishes Arm-R-Seal.

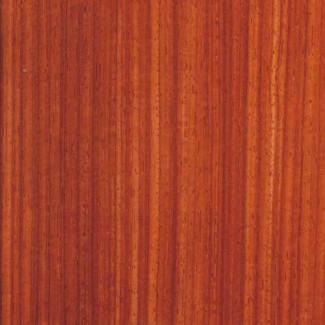

Oily woods can be tricky with any topcoat. The high oil content affects the drying process of the finish coats and Padauk has a very high oil content. Sometimes oily woods dry fine and sometimes they take weeks.